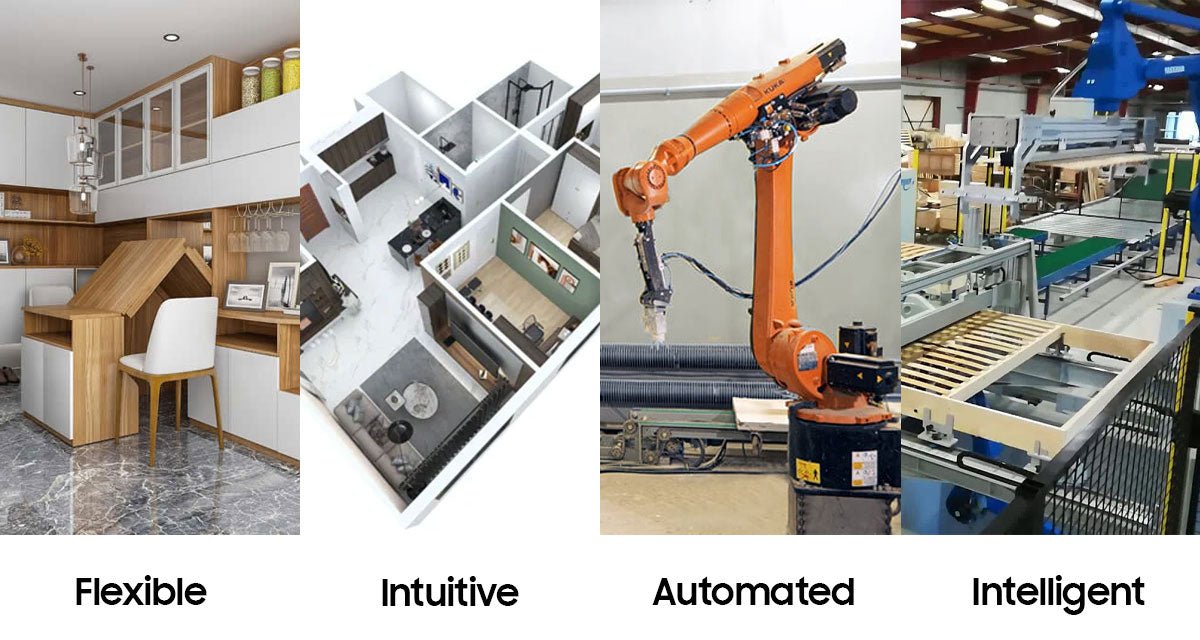

The furniture industry has undergone several transformations over the years, and with the advent of Industry 4.0, the changes are even more profound. The latest in design for furniture incorporates advanced technologies such as 3D printing, artificial intelligence, virtual and augmented reality, internet of things, and robotics. In this article, we will explore the latest trends in design for furniture, their benefits, and limitations.

Feature: Kitchen Cabinet Designs Using Industry 4.0 Software

Introduction to Industry 4.0 Design for Furniture

The furniture industry is embracing Industry 4.0, which entails leveraging transformative emerging technologies for automation and data exchange in manufacturing. Through advanced technologies, designers, developers, and manufacturers can create innovative, efficient, cost-effective, and sustainable furniture designs for the masses in a cost effective way.

What is Industry 4.0?

Industry 4.0 refers to the fourth industrial revolution, characterized by the integration of physical, digital, and biological systems, driven by transformative emerging technologies such as the Internet of Things (IoT), cloud computing, big data, artificial intelligence, and robotics. This integration has the potential to revolutionize the manufacturing industry by enhancing efficiency, lowering costs, and elevating product quality.

Feature: Dining Room 3D Instant Render Design

Benefits of Industry 4.0 Design for Furniture

The benefits of this type of design for furniture are numerous. They include:

Increased Efficiency

By leveraging Industry 4.0 technologies such as robotics, artificial intelligence, and the Internet of Things, the manufacturing process for furniture can be significantly optimized. These technologies enable faster production times and improved product quality, all while enhancing efficiency in the manufacturing process.

Customization

This kind of design for furniture allows for customization of furniture to meet individual customer needs. This is achieved through the use of advanced technologies such as 3D printing and virtual reality.

Sustainability

Such high tech design for furniture promotes sustainability by reducing waste and the carbon footprint of the manufacturing process. The use of advanced technologies also reduces the amount of material used in the manufacturing process.

Feature: ID Gallery - Laundry Cabinets

The Latest Technologies Used in Industry 4.0 Design for Furniture

Such design for furniture involves the use of advanced technologies such as 3D printing, artificial intelligence, virtual and augmented reality, the Internet of Things, and robotics.

3D Printing

3D printing is a process of creating a physical object from a digital file. It involves the layer-by-layer deposition of material until the object is complete. 3D printing allows for the creation of complex designs that were previously impossible to produce using traditional manufacturing methods.

Artificial Intelligence

Artificial intelligence involves the use of machines to perform tasks that would otherwise require human intelligence. Manufacturers can significantly optimize the furniture manufacturing process by utilizing this technology combined with robotics and the Internet of Things. The result is increased efficiency, faster production times, and improved product quality. These improvements translate to faster production times and improved product quality. Enhancing efficiency in the manufacturing process significantly.

Virtual and Augmented Reality

Virtual and augmented reality are technologies that allow for the creation of immersive experiences. Designers of Industry 4.0 furniture utilize virtual and augmented reality to create 3D models of furniture designs, improving customer visualization of the end product. This technology also allows customers to see how furniture would look in their space before making a purchase.

Feature: Bedroom Carpentry Made Easy And High Quality

Internet of Things

The Internet of Things involves the connection of devices to the internet, allowing for the collection and analysis of data. In Industry 4.0 design for furniture, the Internet of Things is used to optimize the manufacturing process, monitor the quality of products, and improve the customer experience.

Robotics

Robotics involves the use of machines to perform tasks that would otherwise require human labor. Industry 4.0 furniture designers utilize robotics to automate the manufacturing process, resulting in reduced production time and increased product quality.

Case Studies of Industry 4.0 Design for Furniture

Several companies in the furniture industry have embraced Industry 4.0 design to create innovative furniture designs. Some of these companies include:

SuoFeiYa

SuoFeiYa is the leader in Industry 4.0 design for the Asian region. They have the largest retail roll out for this technology in the world. All their 3,000 retail outlets are staffed with designers using this technology to customized solutions to direct customers. To date their first and most successful international foray has been with Picket&Rail in Singapore.

Feature: Baby Cot Convertible Companion Cabinets

IKEA

IKEA is a furniture company that has embraced such design technology to create sustainable furniture designs. The company uses 3D printing to create prototypes of furniture designs, reducing the time and cost of traditional prototyping methods. IKEA has also embraced the Internet of Things, using sensors to monitor the quality of products and improve the customer experience.

Herman Miller

Herman Miller is a furniture company that has embraced Industry 4.0 design to create furniture that is customized to meet individual customer needs. The company uses virtual and augmented reality to allow customers to visualize how furniture would look in their space before making a purchase.

Steelcase

Steelcase is a furniture company that has embraced Industry 4.0 design to create furniture that promotes employee well-being. The company uses sensors to monitor employee movement and behavior, allowing for the creation of furniture designs that promote ergonomics and comfort.

Challenges and Limitations of Industry 4.0 Design for Furniture

Despite the numerous benefits of Industry 4.0 design for furniture, there are also several challenges and limitations that need to be addressed. These include:

Cost

The cost of implementing Industry 4.0 technologies can be prohibitive, especially for small and medium-sized furniture companies.

Skills Gap

The implementation of Industry 4.0 design for furniture requires skilled labor, which may not be readily available in some regions.

Data Security

Industry 4.0 design for furniture involves the collection and analysis of data, which may pose a risk to the privacy and security of customers' data.

Conclusion

In conclusion, Industry 4.0 design for furniture involves the use of advanced technologies to create innovative furniture designs that are efficient, cost-effective, and sustainable. The latest technologies used in Industry 4.0 design for furniture include 3D printing, artificial intelligence, virtual and augmented reality, the Internet of Things, and robotics. While Industry 4.0 design for furniture has numerous benefits, there are also several challenges and limitations that need to be addressed.

Recommended Links

- Customized Furniture

- Customized Tatami Storage Beds

- Customized Bunk Beds

- Customized Wardrobes

- Customized Kitchen Cabinets

- Galleries.

- Follow our facebook page for the latest articles, news and deals.